Lucid Motors calls its motor design miniaturized, and it’s lengthy boasted that the sunshine and “impossibly compact” motor in its Air electrical sedan is lean sufficient to suit into an airplane carry-on.

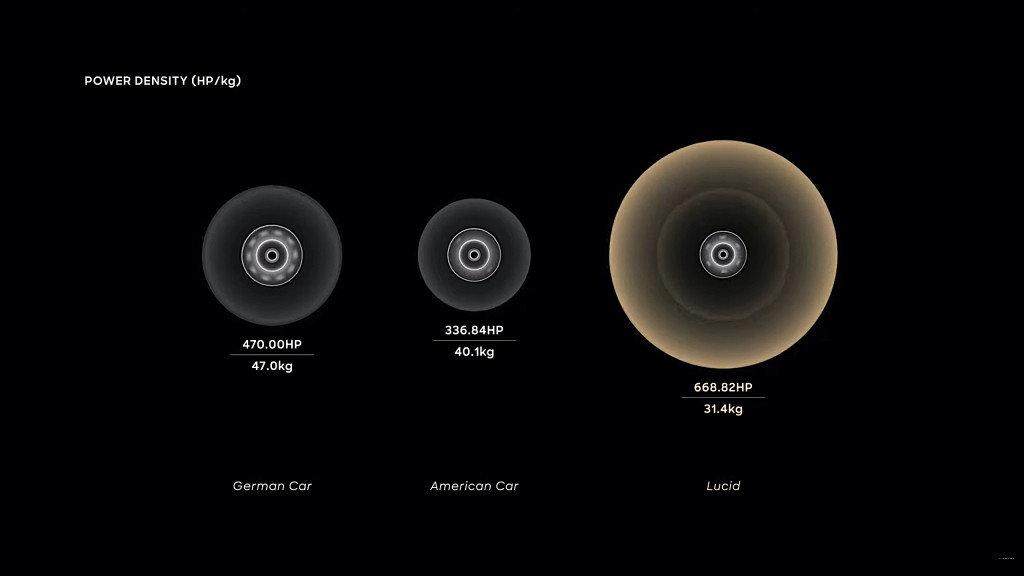

Lean and small is just one facet, nonetheless. Lucid’s motors weigh simply 67 kilos every and are able to producing 670 hp—sure, that’s 10 hp per pound.

2022 Lucid Air

Additional, Lucid’s silicon carbide inverter, discount gearset, and differential, packaged collectively, weigh about 163 kilos.

It is vitally, very power-dense. And in a tech speak launched by the corporate on Tuesday, Lucid CEO and CTO Peter Rawlinson and Powertrain VP Emad Dlala ran by the priorities the motors had been designed round, and the way energy and effectivity, by low resistance and thermal administration, have been a part of the plan from the beginning—together with ease of producing.

You’ll need to watch your entire presentation—greater than an hour—for the physics lesson inside, and also you’re certain to be taught rather a lot not nearly this unit however motors usually. However these 4 slides, evaluating Lucid’s motor to motors from Tesla and Porsche, get to the gist of it.

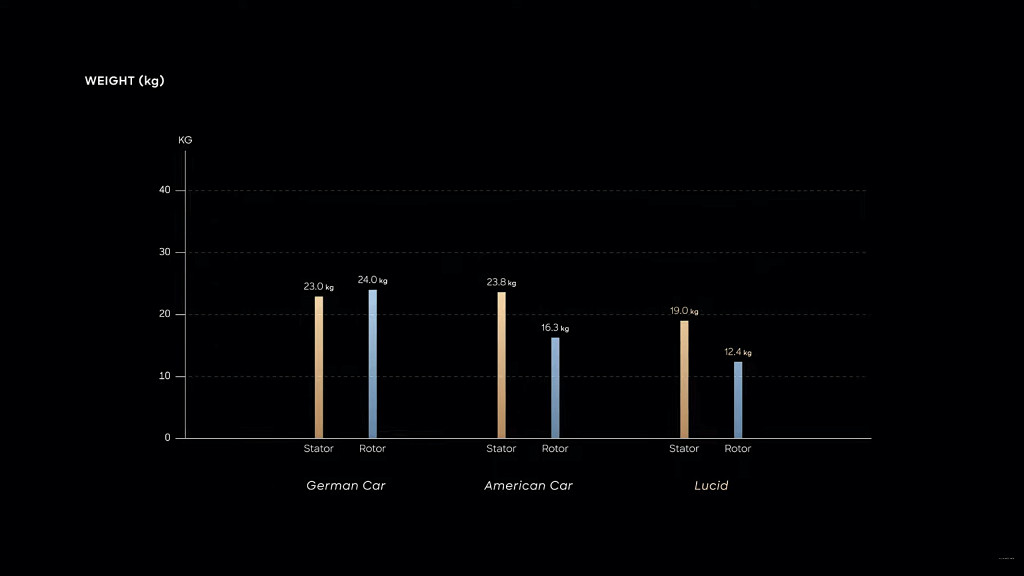

Lucid weight of stator and rotor in contrast

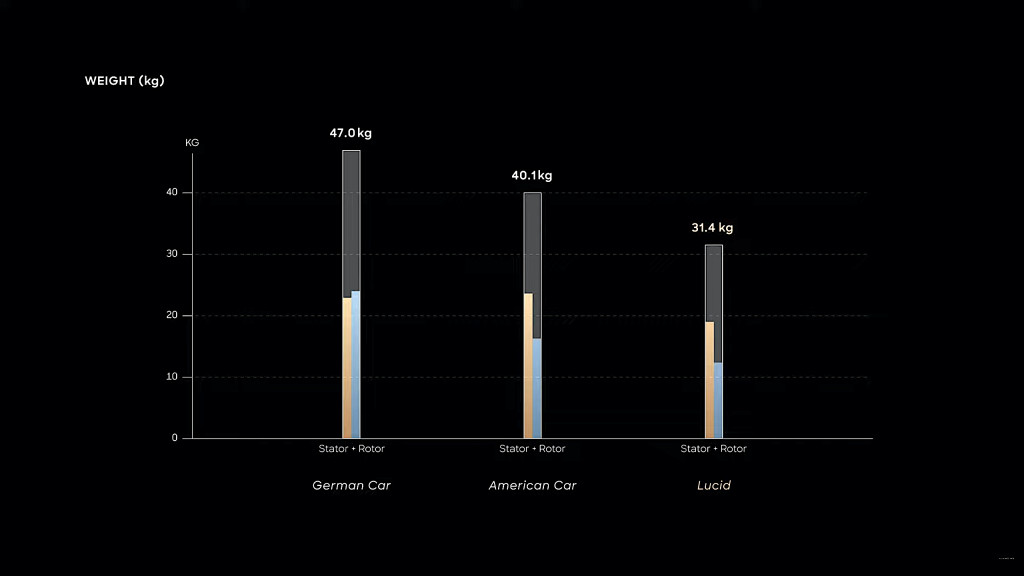

Lucid motor weight in contrast

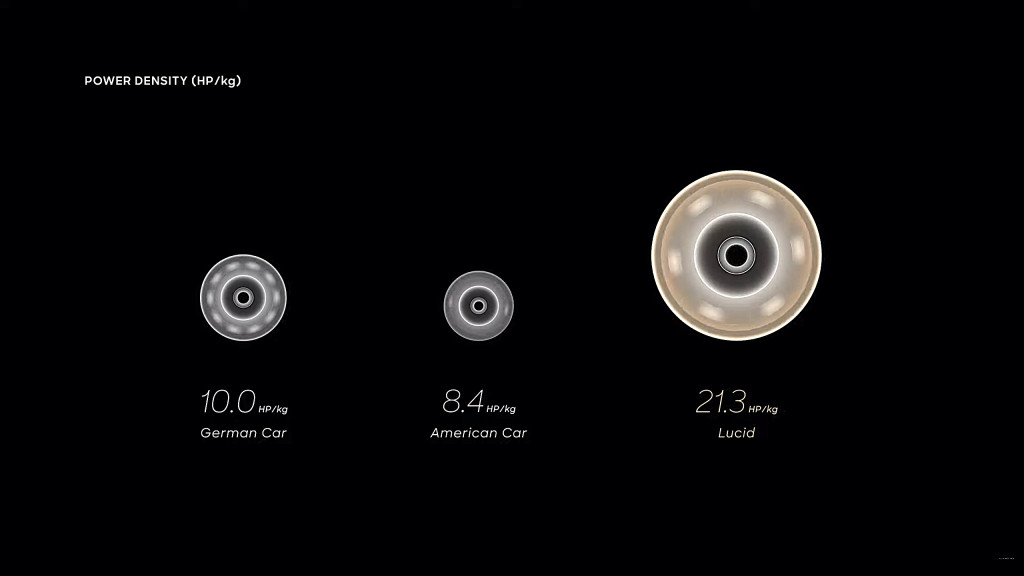

Lucid energy density in contrast

Lucid energy and motor weight in contrast

Rawlinson notes that the mission included going again to the physics and searching on the entire powertrain as a single holistic inertial system.

The 2 spend a lot time discussing the design of the stator—the static outer portion of the motor that, with the present formed by the inverter, creates the magnetic discipline that rotates the rotor within the center.

As an illustration, the stator for Lucid’s six-pole permanent-magnet synchronous motor doesn’t use copper-wire windings like many such motors, and it doesn’t use hairpins both. As a substitute, for decrease energy losses plus ease of meeting, Lucid seems to a continuous-winding meeting that wraps into the stator with a restricted variety of welds. It’s made with a CNC-controlled machine and a course of that resembles weaving. Then a CNC-controlled mandrel helps align and insert the woven mesh.

Carbon wrap on Tesla Mannequin S Plaid motor

The pair even poke somewhat enjoyable on the workaround that Tesla resorted to in its motors for the Plaid—a carbon-fiber shell that Rawlinson notes is similar form of expertise utilized in hydrogen storage for gasoline cells, to carry large strain in. To scale that to excessive quantity goes to be very costly, Dlala speculates.

Lucid additionally cools its motor in another way than Tesla, Porsche, or another designs we’re conscious of. Lucid’s technique extracts no matter warmth it might super-close to the slots somewhat ready till the warmth reaches outward. A center channel within the stator features as a manifold, working ATF (automated transmission fluid) by slender channels, serving to extract warmth by that mesh.

The busbars connecting the motor to the inverter are additionally the shortest attainable, to cut back resistance (and thus warmth). It’s a bonus of the motor because it was designed in a single unit with the inverter.

Lucid’s Rawlinson and Dlala presenting drive unit

Backside line: Lucid emphasizes that its drive models are mild, compact, environment friendly, power-dense, and may be scaled up.

Though Lucid doesn’t truly lay out an effectivity evaluation of the motor unit versus the unit from the Taycan and Mannequin S Plaid, it implies primarily based on the entire presentation that its motors additionally make an enormous contribution to effectivity.

To that time, Rawlinson ventures that the motor itself weighs so little—simply 11% of the general battery-pack mass—that if they will obtain that achieve in effectivity from the unit’s design it’s primarily a “zero mass drive unit.”

Which may be the purpose to assist allow a bonus for Lucid sooner or later, because it produces EVs that go farther with smaller battery packs and, maybe, a scaled-down model of this unit.