We take a more in-depth look as Mercedes-AMG ONE manufacturing commences.

Mercedes-AMG dropped us a line throughout the week to remind us that manufacturing has lastly commenced on its extremely anticipated all-new System 1 expertise ONE hypercar.

AMG went on to clarify the automobile’s unique manufacturing course of because it prepares for first buyer deliveries later this 12 months. Solely 275 ONEs shall be constructed.

ONE Energy Trains Constructed Alongside Hamilton’s

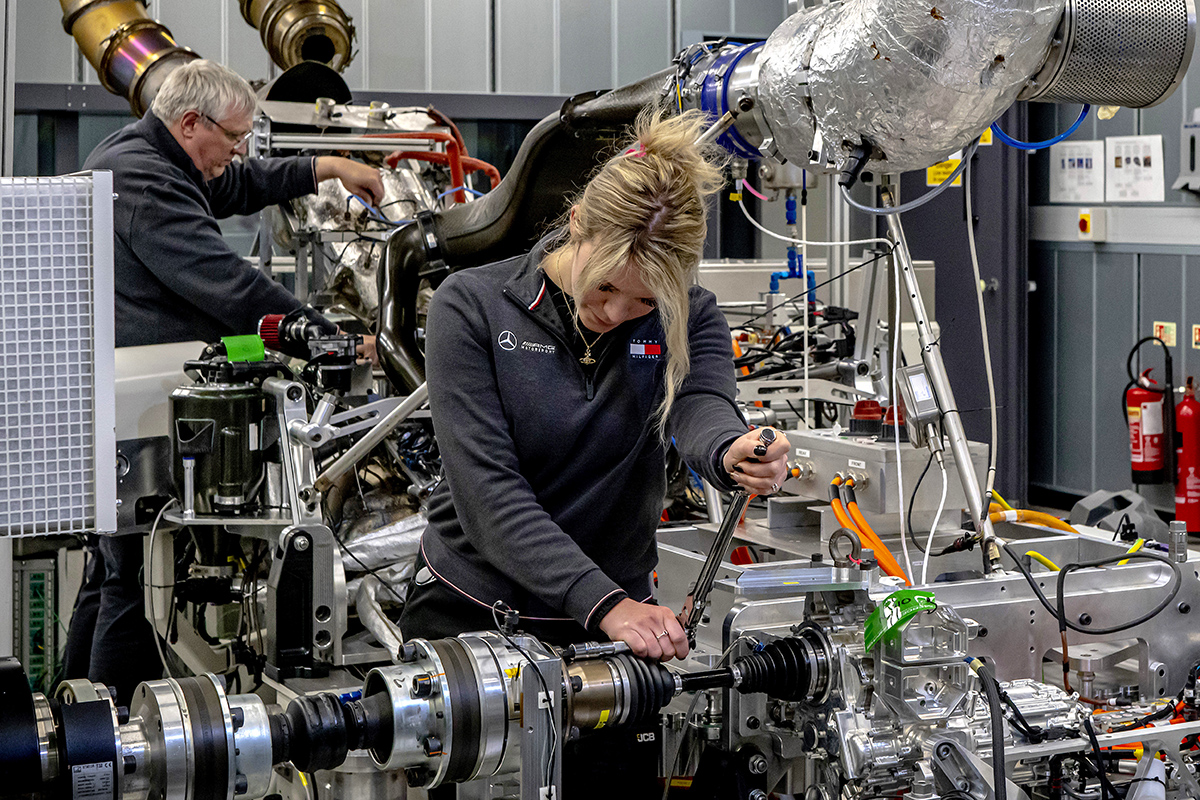

ONE’s System 1 primarily based 1.6-litre turbo V6 engine is a part of a hybrid powertrain with 4 electrical motors. Energy items are constructed alongside Lewis Hamilton and George Russell’s Mercedes-AMG F1 race items by the System 1 workforce at Mercedes-AMG Excessive Efficiency Powertrains in Brixworth England. Assembled items are then despatched to Multimatic in Coventry, England, the place they are going to be mated to ONE’s chassis on the small, devoted collection manufacturing facility.

Mercedes-AMG ONE hand-built manufacturing passes 16 meeting and testing stations paying homage to high-end luxurious watch manufacture. Varied elements are first pre-assembled and examined earlier than being stripped once more and meticulously ready for closing set up.

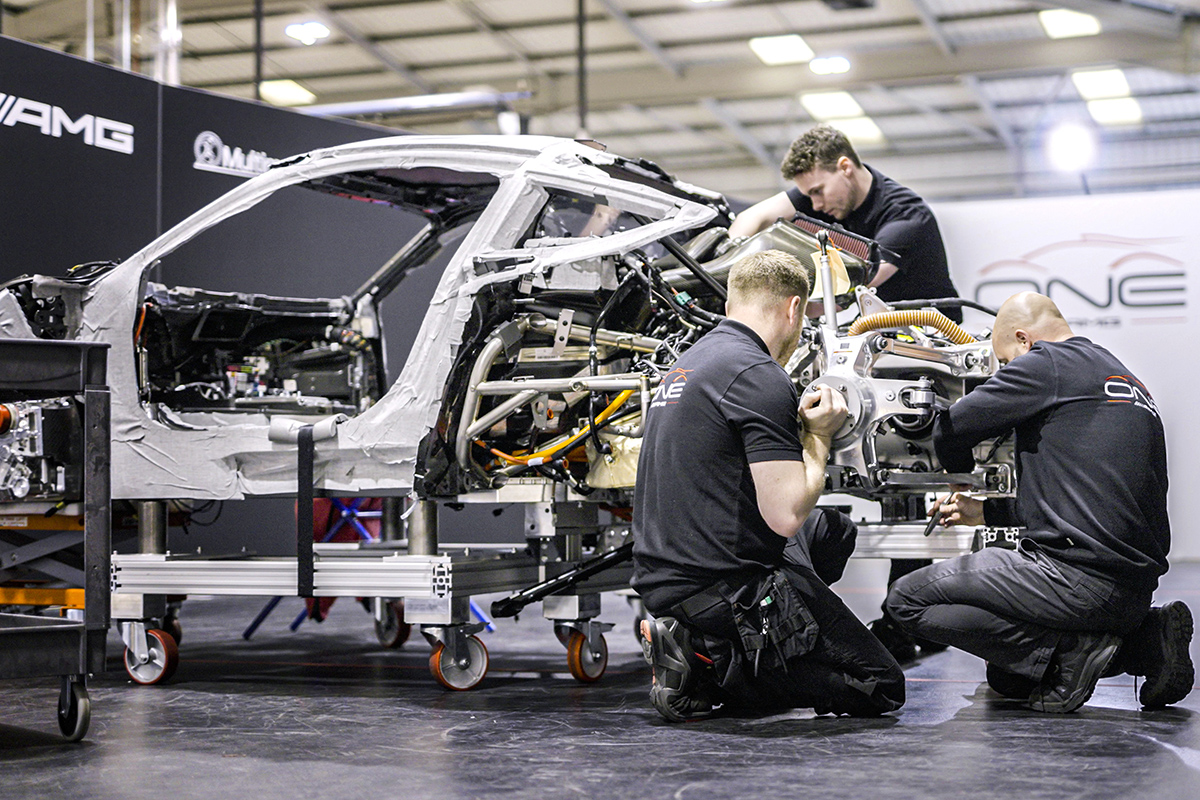

ONE’s carbon-fiber monocoque and bonded roof, its particular person physique elements and full outer pores and skin are first to assembled with all matches meticulously adjusted to completely align.

Every ONE is Made to Actual Buyer Wants

That course of considers each closing lacquering and the carbon-fiber elements’ 1.2 millimeter gauge. As soon as positioned, the doorways, hoods and panels are as soon as once more stripped and individually hand-painted to every proprietor’s explicit style. This additionally ensures an ideal colour match throughout the complete automobile. Then it’s time to mate the powertrain and the body-in-white.

Like Mercedes’ System 1 energy items, ONE’s engine, 4 electrical motors, their inverters, the high-voltage battery and every automobile’s energy electronics arrive prepared and bench examined to mount from Brixworth. Manufacturing continues with the meeting of important powertrain elements, mechanical and low-voltage elements. Excessive-voltage batteries and connections. The combustion engine is then fired up and it and the electrical motors checked and examined.

Each Element is Meticulously Ready

ONE then heads for the inside store, earlier than ready physique panels are fitted. The wheel store contains headlamp alignment, earlier than the all essential dyno take a look at on the rolling street. Noise, monsoon and closing visible inspections observe. earlier than roll-out concludes at a close-by proving floor. A manufacturing unit driver then exams every automobile, earlier than it’s transported to AMG headquarters for handover.

“The Mercedes-AMG ONE is probably the most bold venture now we have ever undertaken,” AMG swimsuit Philipp Schiemer explains. “It marks a excessive level in our strategic growth in the direction of an electrified Way forward for Driving Efficiency. Unique small collection manufacturing is a very distinctive problem and ONE represents a proud world first for Mercedes-AMG in Affalterbach, the System 1 specialists at Brixworth and our manufacturing associate Multimatic.

Photographs: Mercdes-AMG

Be part of the MB World boards now!

Associated Articles

« Earlier Article

« Mercedes-Benz CLK 430: Is a 23-12 months Previous Vert Nonetheless Commuter Worthy?