Nothing is extra irritating for the car proprietor than a puddle of oil on their carport fl oor or the stench of oil on a sizzling engine or exhaust system following a lube service. It’s equally irritating for the lube store asthey should right the issue, shedding billable labor time.

We now have seen clients return following a lube service with an oil leakage grievance and the lube technician putting in a second or third oil filter in a futile try to right the leakage grievance. It’s unlikely that you’ll encounter a number of oil filter failures, consecutively. Failure to precisely diagnose the reason for the leakage may end up in the shopper shedding confidence within the store’s skill to correctly service their car, and you’ll probably lose a buyer within the course of.

If proof of oil leakage is current previous to performing the lube service, the shopper ought to be made conscious of the situation and documentation ought to be made on the restore order. Usually, the technician will get blamed for a situation which will have been inherent within the car previous to the lube service. This text will illustrate some sources of potential leakage that ought to be thought of when diagnosing leakage complaints. When leakage complaints contain functions which can be fitted with oil coolers, particular consideration have to be given to these parts and associated gaskets/O-rings.

MOPAR OIL COOLER LEAKAGE

Chrysler, Dodge and Jeep functions geared up with 2.0L and a pair of.4L engines could encounter oil cooler leakage which may be misdiagnosed as oil filter leakage. These functions name for the M48 sequence filter. A clean-up of the realm would be the first step required to pinpoint the supply of the leak.

The engine facet of the oil cooler is sealed to the engine with a gasket/O-ring secured by a connector bolt. The alternative finish of this bolt additionally serves because the oil filter attachment level. The bolt ought to be torqued to 36 ft. lbs. (see Fig.1). It’s attainable for the connector bolt to loosen within the technique of a number of oil filter adjustments, leading to leakage. Eventual gasket compression may also happen, requiring a substitute gasket between the cooler and engine.

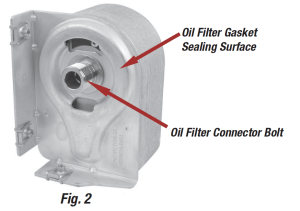

The oil filter facet of the oil cooler (see Fig. 2) ought to be inspected for harm or deformation that might forestall the oil filter gasket from sealing correctly to the cooler. The cooler is a stamped piece of steel and never a machined floor just like the engine block. Overtightening the connector bolt may end up in harm or distortion to the cooler. A bolt that’s not correctly torqued can loosen when performing oil filter adjustments, particularly if the oil filter was beforehand overtightened.

NISSAN OIL COOLER LEAKAGE

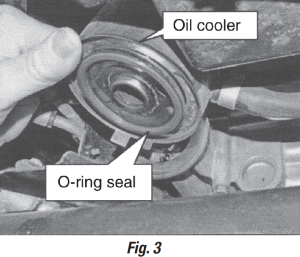

Oil cooler leakage has plagued Nissan functions geared up with VQ30 (3.0L) and VQ35 (3.5L) engines for the reason that yr 2000. The identical oil cooler association is included with present manufacturing automobiles. These functions name for the M4612 sequence filter, which has been mistakenly blamed for the oil leakage. The leakage happens because of a poor seal between the oil cooler O-ring and the engine. Nissan has a revised O-ring for the oil cooler, which isn’t a typical O-ring, requiring a visit to the seller (see Fig. 3).

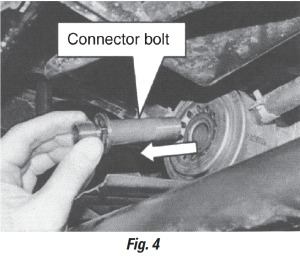

Nissan recalled sure manufacturing automobiles together with: 2011- 2012 Nissan Frontier, Xterra, Pathfinder and Nissan NV automobiles. A number of the connector bolts that safe the oil cooler to the engine had been manufactured under specification energy. The bolts could break on the oil filter attachment level leading to leakage (see Fig. 4). The torque spec for the connector bolt is 36 ft. lbs.

CHRYSLER’S 3.6L PENTASTAR ENGINE

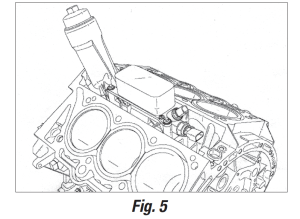

Filter housing and cooler leakage has plagued Chrysler’s 3.6L Pentastar engine. The plastic housing and cooler meeting is positioned beneath the consumption manifold between the cylinders (see Fig. 5). This space could accumulate a quart of oil earlier than displaying any signal of a leakage. This will forestall the technician from observing any leakage following the lube service. When altering the oil filter, the cap shouldn’t be overtightened. The cap is stamped with a torque spec of 25 Nm (18 ft. lbs.). Overtightening can harm the cooler housing within the type of cracks or disturbing the housing O-rings, selling oil or coolant leakage.

It makes good enterprise to test for oil pooling beneath the consumption (engine valley) on any utility fitted with the identical oil filter/cooler association previous to performing a lube service. Performing this service could forestall you from having to soak up some pointless elements and labor prices.

To test for oil pooling within the engine valley, fabricate a dip stick (ideally of wooden) and insert it subsequent to the oil filter housing, and permit it to backside out within the engine valley.

If oil is pooling on this space, the oil filter/cooler housing will more than likely require substitute. A small quantity of oil (wetness) on the tip of the fabricated dip stick could also be the results of spillage when altering the oil filter and ought to be no reason for concern.

The presence of oil pooling on this space requires a direct dialogue with the car proprietor previous to performing a lube service. If the shopper is just not receptive to having the housing changed, make sure you doc your advice on the restore order and retain a duplicate. We now have learn reviews of automobiles encountering fires because of oil leakage from the oil filter housing. For added data and illustrations, discuss with Tech Tip 180 Chrysler’s 3.6L Pentastar Engine.