Tesla CEO Elon Musk, in Thursday’s annual shareholder assembly, known as himself “a useful accelerant” to the corporate’s future, as shareholders authorized a pay package deal for Musk valued at $46 billion primarily based on present inventory costs.

In the meantime, one side that was resulting from change the corporate’s trajectory, lower prices, and allow every little thing from a $25,000 Tesla EV in 2023 to mass-production of the Semi in 2021 hasn’t but arrived in 2024: the dramatic price reductions of Tesla’s 4680 cells.

“With respect to our personal cell manufacturing, we do see a path to price parity by the top of this yr—a really tough path to price parity,” Musk summed.

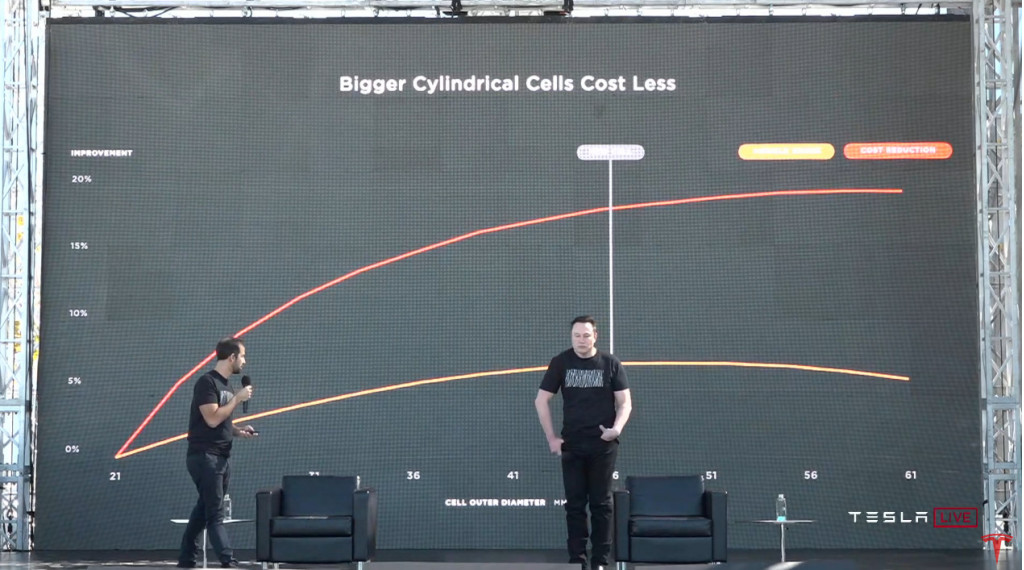

Battery Day and 4680 aimed to halve the associated fee

Whereas Musk is now speaking about price parity, it’s a really totally different actuality for Tesla’s signature battery transfer, practically 4 years after its September 2020 Battery Day. Tesla made the 4680 cells and its personal future manufacturing of them the centerpoint of that occasion and claimed it might make the breakthrough cell at half the associated fee, on an power foundation, versus suppliers—and boasted that it might even provide it to different automakers.

Evaluating 4680 vs. 2170 – Panasonic

“At present our 4680s price greater than our suppliers’,” Musk revealed on Thursday, as he famous the volatility of EV battery costs. “They price greater than the suppliers’ at present however they price lower than the suppliers’ a yr in the past.”

“There’s a little bit of a feast-famine factor with battery cell suppliers, type of for VRAM chips,” he added. “However we count on to realize price parity, even be a lot decrease than the provider cell worth at present, by the top of the yr.”

Tesla’s large battery wager hasn’t paid off—but

The price of EV battery cells has certainly been a rollercoaster trip. After Battery Day, EV battery price soared to new heights in 2022, hampering EV affordability. Lithium-ion battery costs dropped via 2023 and into this yr, however they’re not exhibiting indicators of stopping. Goldman Sachs analysts now anticipate an almost 40% decline in EV battery costs between 2023 and 2025, which in flip will enhance gross sales.

Tesla Battery Day – Greater prices much less

In so many respects, the economics of EV battery provide are wanting very totally different than how they introduced round Battery Day. There may be now such a world glut in battery manufacturing, when you take into account China, that China itself now makes sufficient batteries to cowl all international EV manufacturing, in accordance with an evaluation earlier this spring by Bloomberg New Power Finance. And in format, no different main automaker has but dedicated to the 4680 cylindrical format (46 mm diameter, 80 mm peak). BMW has, as an example, as a substitute dedicated to 4695 (similar 46 mm diameter, higher 95 mm peak).

Musk had mentioned in 2021 that with out Tesla’s personal manufacturing of the 4680 cells, it wouldn’t have sufficient for mass-production of the Semi—a stage of Semi ramp that Musk solely confirmed on this week’s occasion.

In 2021, Panasonic’s prime battery government mentioned that mass-producing the 4680 cell format would “require new methods.” However that didn’t cease different prime battery suppliers from vying to make the brand new format.

2025 Tesla Cybertruck – Courtesy of Tesla, Inc.

Tesla’s VP of engineering Lars Moravy did give an replace on 4680 manufacturing in the course of the firm’s Q1 monetary name in April, suggesting it’s at a charge resulting in about 7 gigawatt-hours per yr, with sufficient to remain forward of the manufacturing ramp of the Cybertruck, which is in any other case the one mannequin to make use of them.

As Musk talked about, Tesla could quickly be capable of match different batteries and battery makers, however half the associated fee nonetheless seems to be as distant now because it did in 2020.