Because it seeks to handle manufacturing points with its present Ultium battery cells, Normal Motors could also be contemplating one thing much more advanced.

First noticed by Motor1, a not too long ago filed GM patent software discusses battery cells with Lego-like shapes meant to accommodate cooling channels. As a substitute of constructing battery modules out of a strong mass of cells and putting in a cooling plate beneath, as GM does with its present EVs, gaps between the cells would assist enhance cooling and prolong battery life, the automaker claims within the software.

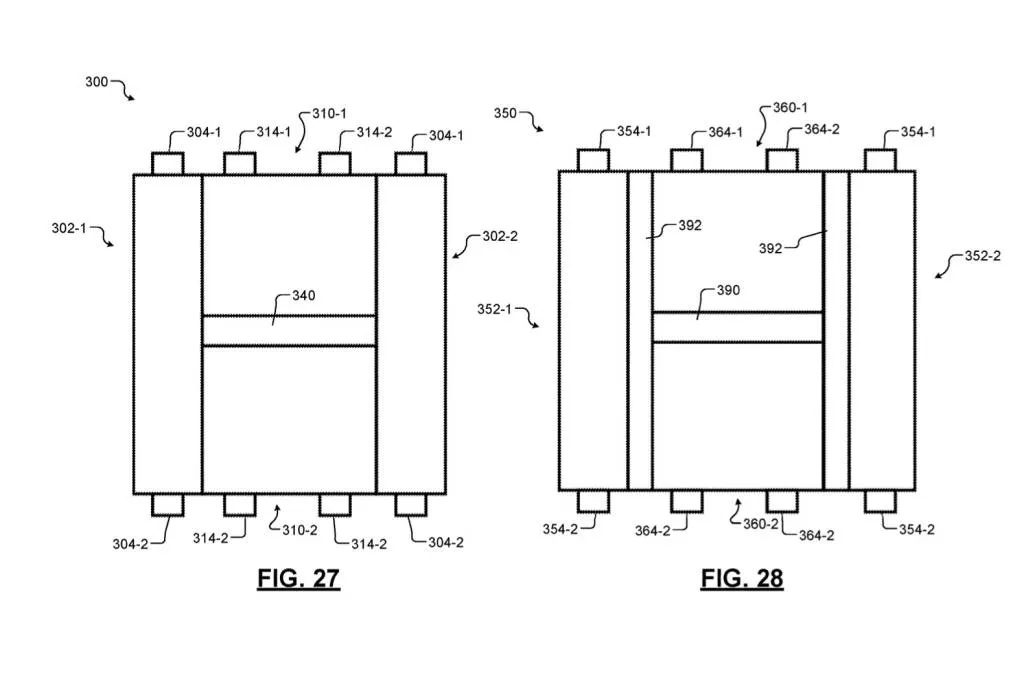

GM additionally claims an identical impact could possibly be achieved with cells with a extra typical rectangular form. On this model, cells of various size and thickness can be organized to create an H-shaped channel within the module to help cooling.

Normal Motors Lego-like battery cell patent picture

Both design would doubtless require GM to stay with roughly rectangular pouch cells, much like what it is at the moment utilizing, quite than the cylindrical cells Lucid, Rivian, and Tesla declare have some thermal benefits, and that BMW is now adopting as nicely.

Automakers do not all the time find yourself utilizing the concepts they patent, so it is unclear if this different type of battery cooling will seem in a manufacturing EV. GM has mentioned that it is versatile in its battery cells, however manufacturing nonuniform cells would doubtless add to the challenges GM is already experiencing in ramping up manufacturing of its Ultium EVs.

GM selected its present large-format pouch cells for being particularly simple to make, however the automaker’s expertise thus far may recommend in any other case. In line with a latest Bloomberg report, the automaker goals to construct 200,000 to 300,000 EVs this 12 months. That might be large enchancment over the roughly 14,000 Ultium EVs offered in 2023, however nonetheless nicely wanting authentic estimates, Bloomberg notes.

Normal Motors Lego-like battery cell patent picture

The report claims GM “bypassed its personal greatest practices” with a purpose to begin Ultium battery-pack manufacturing shortly. For instance, it skipped the everyday take a look at of automated meeting line gear, putting in the gear in its “Manufacturing unit Zero” in Detroit with out that testing. And it particulars battery-related fires at Manufacturing unit Zero, together with one which began after a forklift pierced a battery pack.

GM has additionally been plagued with software program points, which put deliveries of the Chevrolet Blazer EV on maintain for months.

GM executives suppose the worst of those points are actually behind the corporate, and that it’s crawling out of the “manufacturing hell” part of the Ultium ramp, in line with Bloomberg. However has GM gotten sufficient management over these points to begin transferring on to new cell configurations?