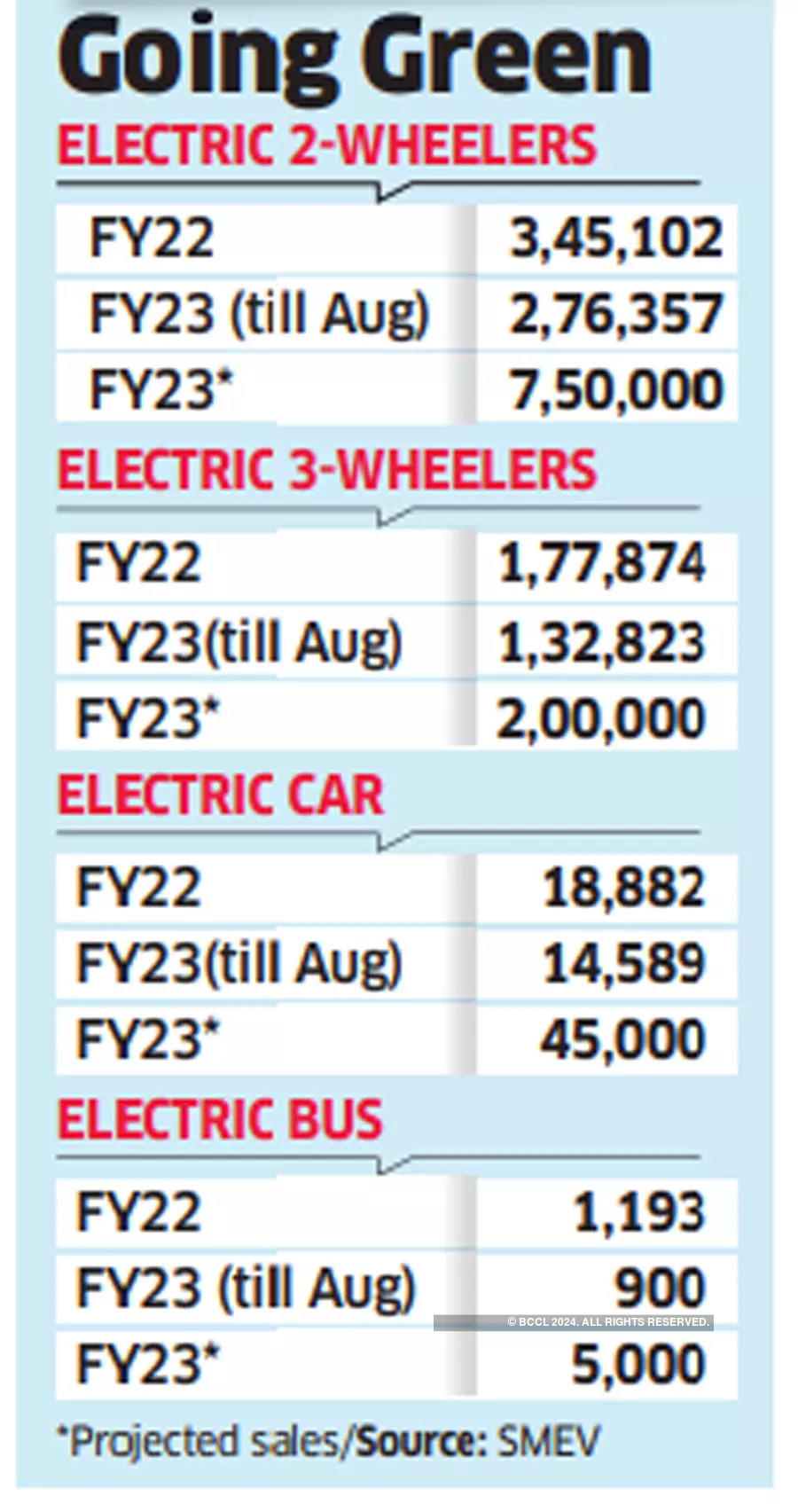

The present fiscal yr is about to be a watershed for India’s electrical car trade. If the previous 5 months are an indicator, EV gross sales will cross 1,000,000 items in FY23, up 84% over final yr.

Main the race are electrical two-wheelers, poised to rise 117% to 750,000 items, adopted by three-wheelers at 12% to 200,000 items. Electrical passenger autos, a section with a small base however two main gamers in Tata Motors and MG Motors, is about to surge 138% to 45,000 items. The e-buses class, which is seeing gross sales traction from state transport firms, is anticipated to succeed in 5,000 items in FY23. All segments, within the first 5 months of the present fiscal, have virtually equalled FY22’s whole gross sales, based on the Society of Electrical Automobile Producers (SMEV).

Towards international markets, India has an extended approach to go in electrification. Whereas it’s displaying progress, penetration continues to be low, stated Ravi Bhatia, president of Jato Dynamics. In India, e-two wheelers nonetheless account for simply 3% of whole ICE two-wheelers, and relating to passenger vehicles, EV contribution is simply 1%.

In distinction, pure battery-operated electrical autos account for 50% of the Chinese language two-wheeler market, and 26% of its passenger vehicles. In Europe and the US, electrical vehicles account for 11% and 5%, respectively of the entire market, Jato Dynamics estimates.

Nevertheless, specialists see India taking to electrical autos in an enormous method. At a latest occasion, Prime Minister Narendra Modi stated that it was probably that the EV sector would quick monitor progress of the complete auto ecosystem.

The latest exponential progress – from simply 5,900 items in FY21 for passenger vehicles – has been spurred by a beneficial coverage atmosphere, optimistic phrase of mouth from present prospects, sensible product choices with higher experience and dealing with vis-a-vis ICE vehicles, rising consciousness of house charging and availability of public charging.

“Now we have been receiving over 1,000 month-on-month bookings for our ZS EV, which inspired us to develop one other EV priced between ₹12 and 16 lakh,” stated Rajeev Chaba, MD, MG Motor India. The corporate expects 25% of its whole gross sales for the FY23 to come back from the present ZS EV and one other car set to launch.

Tata Motors can also be bullish, with plans to launch 10 new fashions, focusing on a contribution of 25% in 5 years.

Low Hanging Fruit “As on YTD we maintain 88% market share pushed by robust response to Tigor EV, Nexon EV Prime and Nexon EV Max,” stated Shailesh Chandra, MD, Tata Motors Passenger Autos and Electrical Mobility.However the true driver of India’s electrification will probably be 2- and 3-wheelers, stated Sulajja Firodia Motwani, chief government of Kinetic Inexperienced Power & Energy Options. “Electrical scooters and three wheelers are the ‘low hanging fruits’, as these are utilized by the lots for last-mile connectivity for its low value of operations,” she stated.

Sohinder Gill, CEO, Hero Electrical, and director common of trade foyer group SMEV, expects that within the subsequent two years, there will probably be extra electrical 2-wheeler product launches, at aggressive worth factors which can enhance penetration.Within the first half of 2022, gross sales of electrical vehicles in China grew by 94%. Europe noticed a progress of 30%, USA at 48%. E-passenger vehicles in India within the first 5 months grew by 322%, based on JATO estimates.

Since India is a market of small and reasonably priced vehicles, electrification will take longer, say specialists, since a majority of the customers are extra worth delicate than their counterparts in Europe or USA. In these markets the typical worth of e-cars is Rs 37-45 lakh. On the similar time, governments have actively labored on offering excessive incentives to spice up the electrical car demand, stated Bhatia.With EV penetration anticipated to go up, the battery manufacturing section stays a vital cog within the total EV ecosystem. Reaching economies of scale in battery manufacturing will stay vital in decreasing the price of an EV and serving to obtain pricing parity with ICE autos, at this time the largest deterrent. ICRA estimates investments in cell manufacturing will exceed $9 billion.

At current, battery cells are usually not manufactured in India, and thus most OEMs depend on imports, and manufacturing operations in India are restricted to the meeting of battery packs, stated Shamsher Dewan, Senior Vice President & Group Head – Company Scores, ICRA. China dominates battery manufacturing at virtually 80%.